Whether you're a DIY enthusiast planning a new lighting setup, a professional tradesperson upgrading a heating system, or an interior designer working on a smart home project, understanding essential electrical components is key. One such core component is the contactor. Despite being often overlooked, contactors play a vital role in many home and commercial installations across the UK. But what exactly are they, and how do they work? Let’s dive in.

Understanding the Basics: What is a Contactor?

A contactor is an electrically controlled switch used for switching an electrical power circuit. It's very similar to a relay but is designed to handle much higher current loads. Typically used in applications such as lighting, heating, air conditioning, and motor controls, contactors allow a circuit to be turned on or off with the use of a control signal, such as a switch, timer, or automation system.

In simpler terms, a contactor acts as a remote-operated switch. It opens and closes a power circuit, allowing heavy electrical devices to operate safely and efficiently. It’s commonly housed in a compact, easy-to-mount casing and found in domestic distribution boards, commercial electrical installations, and industrial machinery.

Especially in smart homes or systems with timed controls and automation, contactors are crucial for managing electrical load without manual intervention. They're reliable, efficient, and safe — making them a smart investment for any serious renovation or new build project.

Contactors are especially useful when remote control of several circuits is needed. For instance, switching outdoor lighting, underfloor heating zones, or multiple appliances through a single switch with minimal wiring complexity is a common use case around UK homes.

How Does a Contactor Work?

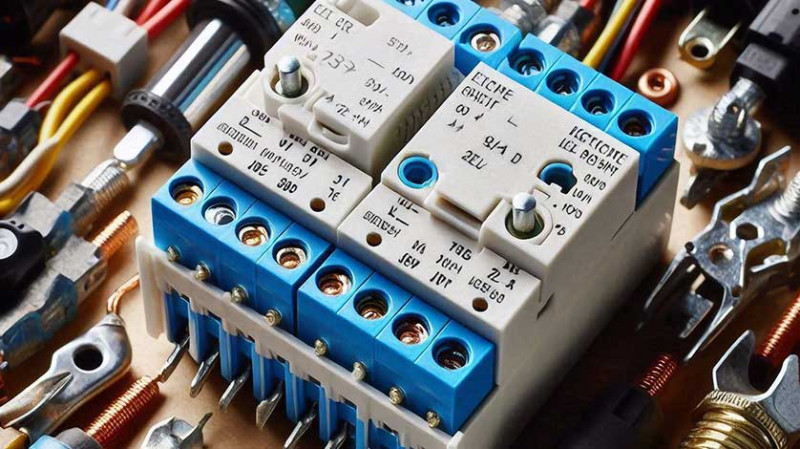

The functioning of a contactor can be broken down into a few key steps. At its core, the contactor consists of three main parts: the coil (or electromagnet), the contacts, and the enclosure. Let’s explore how each part works together.

When an electrical current passes through the coil, it generates a magnetic field. This magnetic force pulls a movable contact (sometimes called the armature) toward stationary contacts. This closes the circuit and allows electricity to flow to the connected load, such as a motor, lamp, or heating element.

When the coil is de-energised — meaning no current is flowing through it — the magnetic field collapses. Springs push the contact back into the open position, breaking the circuit and cutting power to the load.

This simple action of magnetic force controlling the physical connection is what enables contactors to switch power on and off reliably, often many times per day. It creates an ideal method of circuit control without needing the user to manually flip high-power switches, which can pose safety concerns and wear issues.

Contactors also typically feature arc suppression methods to prevent damage caused by the electric arcs that can form when contacts open or close. This not only increases lifespan but also boosts user safety — a major advantage for both homeowners and electricians.

Main Components of a Contactor

To better understand how a contactor operates, let’s break down its four main components in more detail:

| Component | Function |

|---|---|

| Coil (Electromagnet) | Generates magnetic force to move the contacts when voltage is applied. |

| Contacts | Conduct electricity when closed. Typically includes main contacts and auxiliary contacts for control purposes. |

| Enclosure | Protects the internal components from dust, dirt, and inadvertent contact; often made of insulating material. |

| Spring Mechanism | Helps return the armature or movable contacts to the default (open) position when the coil is de-energised. |

Most contactors also feature terminals for both power and control wiring, ensuring clean, safe connections inside consumer units or control panels.

Where are Contactors Used in UK Homes and Buildings?

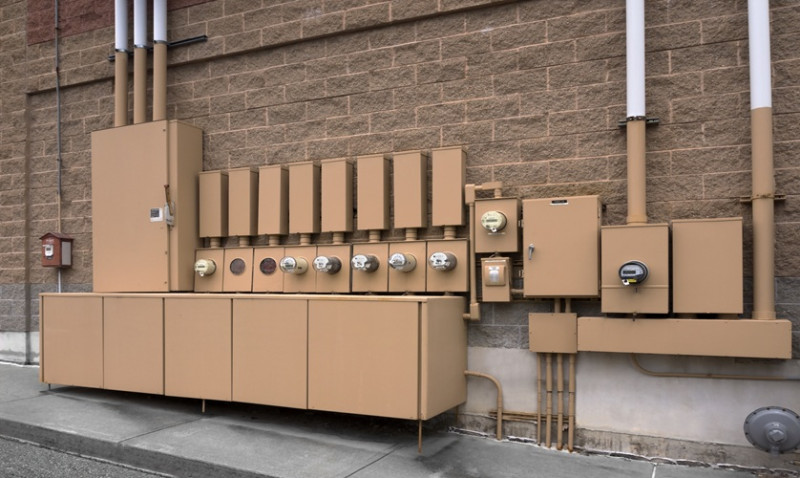

In the UK, contactors are commonly used in domestic, commercial, and industrial settings, making them familiar to everyone from building owners to kitchen fitters and electrical engineers. Here are just a few real-world applications:

- Electric heating systems: Many electric heaters and underfloor heating systems use contactors to manage heating zones via thermostats or timers.

- Lighting circuits: In larger homes, gardens, or commercial buildings, contactors allow multiple lighting circuits to switch remotely or automatically using sensors or control panels.

- Motor control: For applications like extractor fans, water pumps or gate motors, contactors ensure safe operation under load.

- Energy management systems: Smart homes might use contactors in combination with solar inverters or smart meters to optimise when and how loads are powered.

Thanks to their reliability and flexibility, contactors have become an integral part of modern British home automation and energy efficiency systems. Many manufacturers provide models tailored for UK installations, mounting into DIN rails within consumer units with ease.

Advantages of Using a Contactor

Installing a contactor in your project opens up a number of benefits – whether you’re working on a cosy flat in Birmingham or a larger renovation in the Lake District.

First and foremost is the level of control they provide. Contactors allow for powerful automation, remote access, and time-based activation without the complexity of running heavy cabling to user-facing switches. This supports simpler designs and cleaner aesthetics – a major consideration for architects and interior designers aiming for modern, minimal living spaces.

Another significant benefit is safety. Since contactors handle switching remotely and autonomously, there’s a reduced need for manual high-voltage interactions. That’s great for peace of mind, especially in systems where multiple loads are managed simultaneously.

For professionals and homeowners looking at long-term installations, contactors offer durability and longevity. Designed to be used repeatedly, some heavy-duty versions are capable of making tens of thousands of operations without issue. Maintenance is minor — usually only requiring an occasional inspection for wear or loose connections.

Finally, energy efficiency comes to the fore. Contactors let you coordinate circuits efficiently with timers or PIR sensors to avoid wasted consumption. This is increasingly important for energy-conscious buyers in the UK amid rising utility costs.

Things to Consider When Choosing a Contactor

Like anything in electrical components, not all contactors are created equal. Choosing the correct one depends on the specifics of your application. Here are a few pointers:

- Current Rating: Ensure the contactor can handle the load of the connected devices. Overrating slightly is safer than using an underrated part.

- Coil Voltage: Match the coil voltage (commonly 230V AC for UK residential use) to the control circuit.

- Number of Poles: Choose a configuration that suits your application — single-pole for simple loads, or three-pole for three-phase circuits.

- Mounting Options: Most UK applications use DIN rail mounting, so confirm the compatibility with your consumer unit or enclosure.

- Auxiliary Contacts: Some setups use auxiliary contacts for added control or feedback to indicators and smart systems.

If you’re unsure, it’s always wise to consult with a qualified electrician — especially when dealing with property-wide installations or large loads.

Conclusion

Contactors might not get the spotlight like designer lighting or smart switches, but they are the unsung heroes keeping your systems running efficiently and safely. From smart home installations to heavy-duty heating control, their role in UK homes and commercial properties is increasing every year.

For anyone planning an upgrade or a new build – whether you’re a forward-thinking designer, a passionate DIYer, or a seasoned installer – understanding how a contactor works and where to use it gives you more options and better results.

Be smart, stay safe, and don’t underestimate the power of a well-placed contactor.